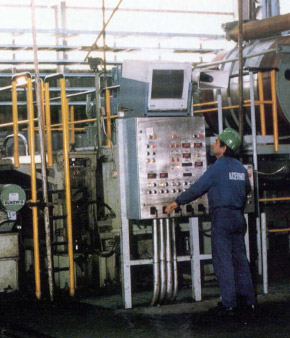

Cold rolling shop

Before pickling, the strip is annealed in an oxidizing-atmosphere furnace to ensure that the microstructure is regenerated and all mechanical properties are recovered.

The annealing process removes oxides and bloom scales from the material surface.

Stainless Steel strip becomes progressively thinner, between 0.25 mm and 6 mm, and harder during cold-rolling. So the material should be annealed to recover the initial mechanical properties.

This process is carried out in a controlled-atmosphere furnace, usually cracked ammonia, in order to avoid later pickling. BA, bright finish is obtained.

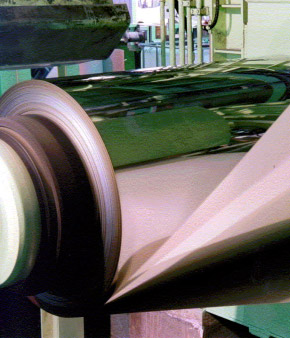

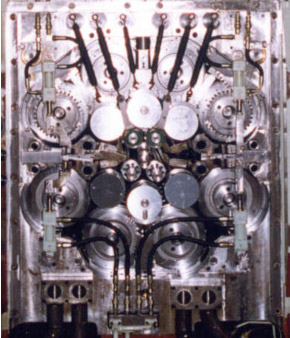

- SKIN-PASS mill

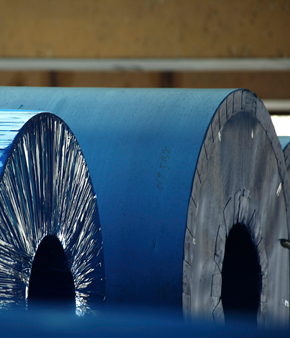

The strip can be smoothing rolled as one further step to improve the surface smoothness and the appearance of the stainless steel. 2B and BA finishes are obtained. - CUTTING

There are different types of cutting: slitter line, shearing line, circle cutting or formats. - PACKING AND EXPEDITION