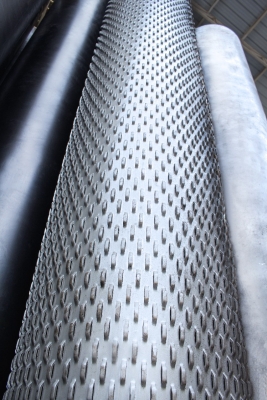

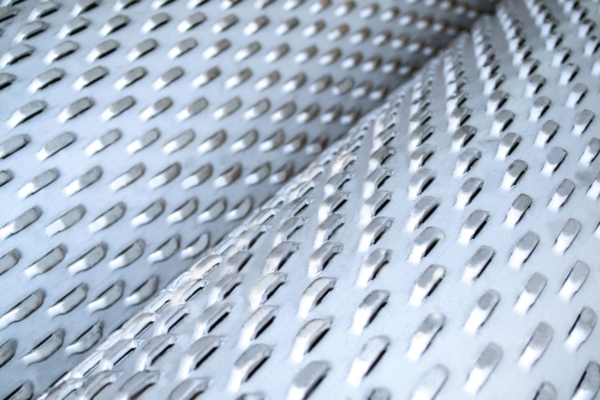

Stainless steel water well screens for bridge slot perforations

Article courtesy of Inamesa Peru

It is difficult to find another invention, apart from the wheel and the discovery of fire that has impacted the most to the development of civilization than the capacity to obtain drinking water.

The first water wells were built in the Neolithic period, almost 10,000 ago. The Earth has incredible natural ways to screen water and human ingenuity takes advantage of it to make possible the access to this vital element necessary to survive.

As human needs increase, agriculture becomes more sophisticated and resources get scarce, the necessity of screening drinking water plays an increasing important role.

Water well screens used today are 100 hundred years old. At the beginning these were hand-made, and as technology advanced, the process was being automated.

INAMESA is a company from Peru with a long history behind, they are national reference in stainless steel manufacturing. They have developed a low cost and very versatile screen well using traditional design and taking advantage of the CNC (Computer Numerical Control) leading technology, which is a good alternative for emerging countries to other more expensive screens.

Stainless steel is fundamental for this application because of its corrosion resistance, durability and easy manufacturing. Therefore, the return on investment of water well makes it very interesting. Depending on the flow and depth of the well, screens can be made to measure, with ranges of 8 to 16 inches diameter and 4 to 6 mm thickness. These sizes are exactly calculated with INAMESA’s own tools. It is important to use stainless steel from an accredited supplier such as ACERINOX to ensure the quality of the material. Stainless steel screens can last up to 10 times more than those made of carbon steel.

For this purpose CNC machinery has been set up with a European design being the end result of a screen with perfect mechanical characteristics, open area and flow. These results are supported by the most prestigious Universities and Institutes of the country.

CNC technology ensured uniform design which has allowed INAMESA to obtain certification from recognized international entities as Société Générale de Surveillance (SGS), being the only SGS certified Company from Peru. Ingenuity and dedication in this new mechanical development have allowed INAMESA to obtain a patent, which is in process of publication.