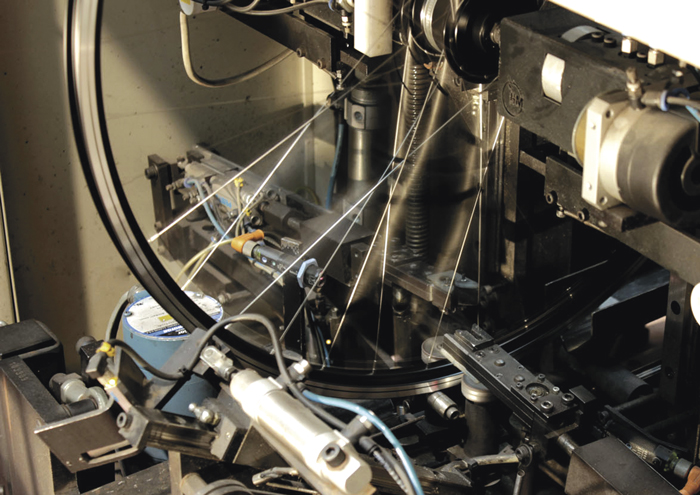

Spokes wire

The stainless steel used for the manufacture of spokes wire, is developed by INOXFIL with a special drawing process to obtain the best results on the final product.

The material is drawn using special dies throughout the whole process. The wire can be manufactured and delivered with or without oil coating, obtaining a shiny and homogeneous wire surface.

The material that requires no oil coating will be degreased in automatic acid based baths and will be cleaned subsequently with water in several rinse baths. All processes are controlled by PLC and internal computer software.

To achieve the best possible product with optimum results of fatigue in the wire it is important to maintain the control over a number of parameters.

INOXFIL supplies the material free of surface defects which are the main cause to loss of fatigue resistance

It is very important to select adequately the correct grade of stainless steel and chemical composition to achieve the desired results during the production of the spokes wire for bicycles, motorcycles or cars.

The recommended grades for this application are AISI 302, AISI 204Cu, and AISI 430, following the cleaning and maintenance practices.

Painted wire:

INOXFIL has developed a special manufacturing process to paint the wire used for spokes, mainly black, where the quality of painted wire in line is very homogeneous and resistant to the process of bending, cutting, threading and stamping.