Combining material advantages

Pdf downloadThe demands on material properties are constantly increasing. In some cases, homogeneous materials can no longer fully meet the requirements set. This leads to the use of composite materials in which the advantages of at least two materials can be combined, and cost benefits can be achieved. One example are clad plates, which have become an indispensable construction material for pipes, chemical and petrochemical plants, power generation plants, exhaust gas and wastewater treatment plants, and chemical tankers.

In most cases, a thicker carbon steel base material is used, to provide mechanical stability, when the plates are further processed to pipes or pressure vessels. The thickness depends on the stress applied to the vessel or component during operation. The base material is always much thicker than the cladding material. The cladding material offers additional features including required corrosion resistance. This thickness depends on the anticipated rate of corrosion loss and or any abrasion which may occur. In the manufacture of chemical process equipment, the thickness tends to be at the upper limit, whereas in flue gas desulphurization plants the cladding thickness is generally at the lower limit. High performance alloys typically used as cladding materials include VDM® Alloy 625, VDM® Alloy 825, or VDM® Alloy 400. Depending on the cladding process used, plates can be manufactured by rollbond cladding, explosive welding or overlay welding.

Rollbond cladding

In rollbond cladding, slabs and/or thick sheets are used as starting material, assembled and heated to material-typical temperatures. Depending on the materials involved, this heating temperature is in the range of 900 °C to 1,200 °C. The plates are subsequently rolled. In the subsequent rolling operation, the plates are rolled to the required dimensions and at the same time the metallic bond is produced. The available dimensions of hot-rolled clad plates are generally limited by the maximum piece weights that can be processed and by the dimensions of the available roll stands. For higher wall thicknesses, other cladding processes are usually used for technological but also economic reasons.

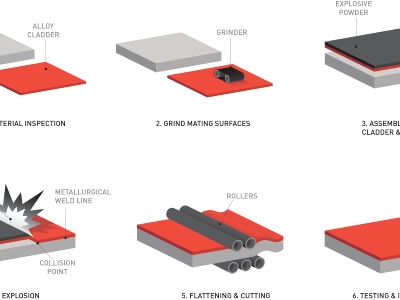

Explosive welding

In the explosive welding process, the cladding material is detonated towards the base material from a defined distance of a few millimeters using the energy of an explosive force with a correspondingly high velocity. The resulting high kinetic energy creates the metallic bond between the materials. The clad materials are available in final dimensions, and only insignificant deformation occurs as a result of the process. Due to the explosive welding process, blast waves with typical wavelengths of a few millimeters are imprinted in the bonding plane. This locally reduces the thickness of the overlay material. The available dimensions are essentially limited by the available starting materials. This process is used, among other things, for the production of very thick clad plates, but also for material combinations that are difficult or impossible to produce by hot-rolled cladding, such as transition joints between carbon steel and aluminum.

Overlay welding

While only flat clad plates are produced in the two processes described above, in many cases weld cladding is performed on the already finished component. In this process, a wide variety of welding processes are used to apply the desired cladding materials in single- or multi-layer welds. Compared with the other two methods, it is no longer possible to speak here of an exactly defined bonding plane. Because of the mixing with the base material, several layers are usually welded on top of each other. Whereas in the others the cladding materials are used in the form of sheets or strips, comparatively expensive weld metal has to be processed here. In addition, of course, each individual weld bead must be inspected in accordance with the usual quality controls for welds.

In addition to its use for local repairs and the creation of so-called supplementary cladding on components made from clad sheet, the great advantage of weld cladding is that this process can be used practically independently of the geometries, wall thicknesses and manufacturing processes of the substrate material. For example, castings or already formed components can also be coated with a protective high-alloy layer. Overlay welding gained more and more importance over the past years. To ensure the suitability of its welding consumables for overlay welding processes, VDM Metals conducts extensive tests in ist Welding Center of Excellence.

Heat treatment

Heat treatment is a critical issue in the case of clad plates. It imparts the desired properties to the composite steel. It may be necessary to assess all options, from raw material composition to appropriate manufacturing parameters including cladding technologies to ensure final mechanical and corrosion properties of the clad plate metal combination.

In a recent project, NobelClad and VDM Metals conducted a series of tests and building a case for VDM® Alloy 825 explosion-cladded plates as a high-quality, reliable clad for highly corrosive pressure vessel environments. The companies set out to prove corrosion properties can withstand cladding, head forming, and vessel manufacturing thus encouraging the attentive selection of partners through out the process.

After setting the right parameters for steel, it was important for NobelClad’s end-to-end supply chain partners to consider how best to maintain Alloy 825’s corrosion-resistant properties at the main manufacturing stages.

VDM Metals manufactured the plates for cladding in Germany. The production process included melting, secondary metallurgical treatment, hot rolling, annealing and surfacing the material. Plates made by VDM Metals pass through stringent quality control protocols. In-process checks and inspections are conducted onsite to ensure full compliance with the required product properties. For this reason, VDM Metals operates its own laboratories to test the exact chemical composition of each alloy, including the alloy’s mechanical properties and corrosion behavior.

ASTM G28 Meth A is the most appropriate corrosion test for Alloy 825. After carrying out heat treatments following manufacturing requirements, VDM cut production plate coupons and conducted the ASTM G28 Meth A tests. Three main manufacturing stages - and the related heat treatments - were considered for coupon preparation:

1. Delivery condition

2. Head heat treatment simulation:

- Head forming at 1,035°C cooling air

- Normalizing plus accelerating cooling at 900oC + water

- Tempering at 650°C cooling air

- Simulated Post-weld Heat Treatment (SPWHT) 3.5 hours at 610oC x 3

3. Shell heat treatment simulation

- SPWHT 3.5 hour at 610°C x 3

Upon completion, the corrosion test results confirmed heat treatment settings in vessel manufacturing produced perfect matches to customers’ requirements. The simulated post-welding heat treatment slightly increased corrosion rates but the rates remain far below 0.9 mm/yr. The ratio is similar between annealed condition and after head heat treatment simulation.

These statistically reliable results confirm the benefit of an end-to-end supply chain in which high-quality suppliers work together to manufacture critical equipment backed by stringent quality control protocols.